Gas ballasts can be found on higher-end vacuum. Used with an oil sealed vacuum pump a gas ballast reduces the amount of vapor condensation and therefore contamination of the pumps sealing-oil.

Vacuum Pump Gas Ballast Operation Youtube

Circulating Water Vacuum Pump.

. KDSD spray dryer machine. Once the cycle has neared its end and a lower pressure is needed the gas ballast can then be closed once all of the water. The correct use of the Gas Ballast valve on a mechanical oil sealed rotary vacuum pump has always been seen as black science or just plain guesswork.

213 prevents condensation of vapors in the pump chamber of the pump. There is very little moisture left in the system once you reach 10000-15000 microns having the ballast open will only slow the evacuation. To do so the pump inlet port should be closed and the pump allowed to run with the gas ballast valve in the open position.

After your evacuation and when you have closed off your manifold or blank-off valve open the gas ballast before switching off the pump. A simple explanation of the gas ballast on a vacuum pump. How Does A Vacuum Pump Gas Ballast Work HVAC Tip.

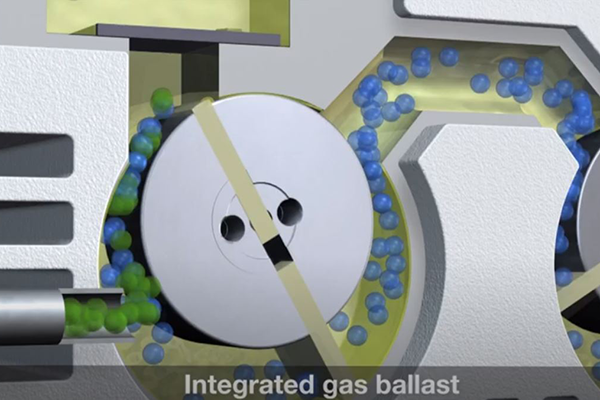

07-10-2011 1251 PM 3. Means through which air or another non-condensing gas is admitted into a vacuum pump are referred to as gas ballast. Before the actual compression process begins a precisely defined quantity of air the gas ballast is admitted into the pumping chamber of the pump.

The quantity is such that the compression ratio of. Continue purging for several hours or overnight depending on the size of the system and the degree of contamination. DHG-9140A blast drying oven.

DZF-6050 vacuum drying oven. The air ballast valve is situated at the top of the vacuum pump next to the suction fitting. If the pump is smoking or exiting oil mist in good quantity.

When the gas ballast valve is opened it will prevent the vacuum pump from fully achieving the vacuum. If pumping water vapor for example at a pump temperature of 158F 70C the vapor may only be compressed to 312 mbar saturation vapor. Take a long lunch or let the pump actuate overnight with the valve open.

EP0711387A1 EP94918783A EP94918783A EP0711387A1 EP 0711387 A1 EP0711387 A1 EP 0711387A1 EP 94918783 A EP94918783 A EP 94918783A EP 94918783 A EP94918783 A EP 94918783A EP 0711387 A1 EP0711387 A1 EP 0711387A1 Authority EP European Patent Office Prior art keywords pump valve membrane oil gas ballast Prior art date 1993-07-28 Legal status. Gas ballasting is an integral part of the successful operation of any vacuum furnace and should be considered a routine part of daily operation. Some HVAC techs that I have spoken to have had no idea what a gas ballast was or that it even existed on a vacuum pump.

Closed medium flow and. The gas stream evacuated from a vacuum chamber contains water vapor solvent vapor and other potential contaminants. The amount of air flow allowed is controlled through a cap located on the exterior of the pump.

Make it part of your routine. 10L double collection short path distillation. This increases the percentage of non-condensable gas such that the partial pressure of the vapour being pumped is below its saturated vapour pressure when the exhaust valve opens typically at a pressure of 105 to 12 bara.

Care again should be considered to the exhaust stream. When pumping vapors these may only be compressed up to their saturation vapor pressure at the temperature of the pump. The gas ballast can be utilized when there are medium or larger amounts of condensable vapors like water in the system.

Quite a number of HVAC techs are not aware of how a vacuum pump gas ballast works or when to open or close it. Some pumps have three positions for the gas ballast. You cannot get into a deep vacuum with it open at all.

By Martin King Posted May 13 2022. The gas ballast facility developed in 1935 by Wolfgang Gaede inhibits the occurrence of condensation of the vapor in the pump as follows. The function of the gas ballast valve is to enable condensable vapours to be discharged through the pump with.

Many heat treaters ballast their vacuum pumps for 20-30 minutes at the beginning of each day while planning their schedules and preparing loads to be run. It is a very simple device and when used correctly can keep a vacuum pump working well even though it may be used on a very wet process and the oil becomes contaminated with condensed vapors. Some pumps also will not pull down with the ballast open.

If there is little moisture it is not even worth opening. If the pump is displacing vapor that would condense in the pump at the corresponding temperatures without gas ballast the gas ballast enables the outlet valve to open before the vapor condenses and the vapor is discharged together with the. The gas ballast facility see Fig.

This again will help purge the pump. A gas ballast is a passageway that leads into the compression side of the crescent cavity allowing for small air flow. A pump that has been subject to condensed vapour can be cleaned-up by using gas ballast.

Close the pump inlet port off to full vacuum and allow pump to runactuate with gas ballast valve in open position. Examining the simple science behind gas ballast valves. Using a Gas Ballast.

The valve must only be shut down finger tight otherwise the precision valve seat may get damaged. The basic principle of ballast is that atmospheric air or CDA or inert gas is admitted into a pump during the late compression stages as above. Gas Ballast Diagram.

In applications requiring a deeper attainable vacuum than with the gas ballast open its recommended to operate the pump with the ballast open to minimize wear on the pump while in the primary evacuation then to close the gas ballast as pressure decreases to attain the required vacuum level. Open when you first start to pull a vacuum - down to 10 or so then close for the rest. It is opened by turning anticlockwise.

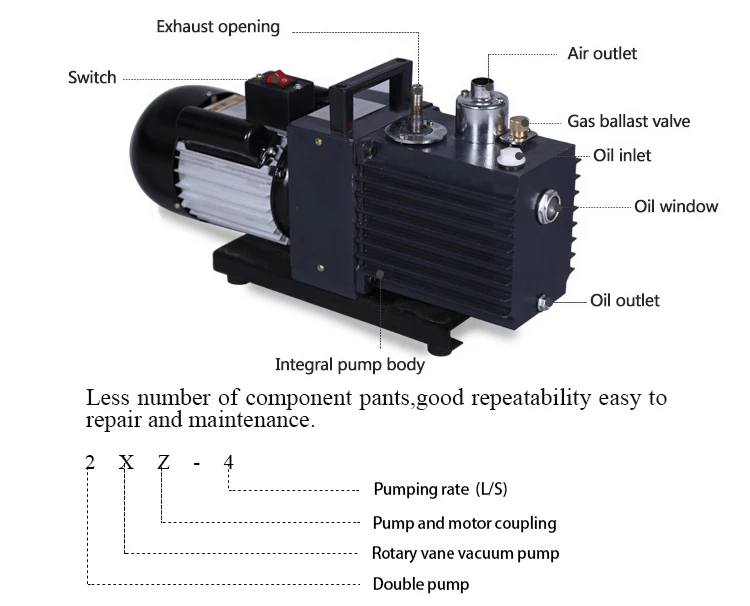

Vane Rotary Vacuum Pump Vacuum Pump Factory

Gas Ballasting Of Vacuum Pumps Part 2 2017 01 10 Industrial Heating

Gas Ballasting Of Vacuum Pumps Part 2 2017 01 10 Industrial Heating

The Simple Science Behind Gas Ballast Valves Leybold

Gas Ballasting Of Mechanical Oil Sealed Rotary Vacuum Pumps

Gas Ballasting Of Vacuum Pumps Part 2 2017 01 10 Industrial Heating

0 comments

Post a Comment